Home » About the Company » Manufacturing Capabilities » Casting Facilities

The company has available powerful foundries, which provide with castings the basic production sector as well as deliveries for cooperation.

The foundries comprise the casting sectors of both high and low pressure, for investment patterns as well as for continuous casting of steel and aluminium founding.

The Company manufactures the castings of grey cast iron, steels, non-ferrous metals and alloys.

JSC «SMNPO – Engineering» manufactures the castings of the following grey cast iron grades: Sch 10, Sch 35 (GOST 1412-85), Chkh1, Chkh2, Kh3, ChKh28D2 (GOST 7769-82).These castings are intended to manufacture parts of pumps for NPP, heavy-duty compressors and chemical equipment, which are operated in conditions of aggressive, toxic, explosion and fire dangerous media, high pressure and wide temperature ranges. The finished castings meet the strict requirements for mechanical properties, microstructure, chemical composition and density. Cast iron is produced in IChT-6 induction furnaces.

Castings weight: from 50 g to 36 000 kg at maximum dimensions of 6000 x 4000 x 900 mm.

For steel castings the following steel grades are used: 20L, 25Л, 20GL, 20GSL, 35GL, 20Kh13L, 12Kh18N9TL, (GOST 977-88). The steel castings are intended to manufacture parts of pumps for NPP, centrifuges and heavy-duty compressors, which are operated in conditions of radioactive media and high pressure. Steel melting is carried out in DSP-1.5, DSP-3 electric arc and IST – 0.4 induction furnaces.

Castings weight: from 10 kg to 2500 kg at maximum dimensions of 1500 x 1000 x 1000 mm.

For investment casting the following steel grades are used: 20H13L, 12H18N9TL, 12H18N12M3TL. The main nomenclature list includes impellers and guide vanes for centrifugal pumps. Steel melting is carried out in IST – 0.4 induction furnaces.

Castings weight: to 20 kg at maximum dimensions of 300 x 300 x 200 mm.

For copper alloys casting the following grades are used: BrO5C5S5, BrO10F1, BrA9G3L, BrO7S13N3, BrO12S2, L63. Casting is carried out in IST-0.16 and IST-0.4 induction furnaces. Pouring is carried out into chill molds, moulds of centrifugal machines and partially in sand forms.

Castings weight: to 200 kg at maximum dimensions of 500x500x300 mm.

For aluminium alloys casting the following grades are used: АК12, АК5M2, АК5М7. Casting is carried out in IAT – 0.4 induction and crucible gas furnaces.

Castings weight: to 150 kg at maximum dimensions of 800x800x300 mm.

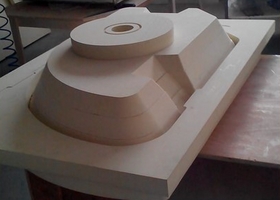

Manufacturing of mold patterns for casting

Manufacturing of wooden models at the machine | Manufacturing of models with a printer |

Products maximum dimensions, mm | Products maximum dimensions, mm |

length – 4000 width – 2000 height – 1000 | length – 800 width – 600 height – 600 |

The equipment allows the production of wooden, plastic, composite materials, aluminum patterns | The equipment allows the production of models for sand molds, burning and investment patterns |