I. PUMPS FOR NUCLEAR POWER PLANTS

JSC “SMNPO – Engineering” is the main supplier of special pumping equipment for all NPP generating units. Nuclear power plants in Ukraine, Russia, Armenia, Bulgaria, China, India and other countries operate with pumping equipment made by the company.

The first pumps were manufactured in 1981. The pumps are manufactured in specialized shops in full conformity with the safety norms and regulations of the State Committee for nuclear Energy Control under the Environment Ministry and are subjected to strict control. The Company has advanced testing facilities. The products have total service life of at least 30 years.

Moreover, the Company manufactures large-sized centrifugal and axial pumps for cooling technical water supply.

Total amount of standard sizes of pumping equipment for NPP manufactured at the Company is more than 90 items.

JSC “SMNPO – Engineering” manufactures the following pumps for NPPs:

Condensate pumps are designed for feed of turbine waste steam condensate, condensate of heating steam from heat exchangers of NPP power units and liquids similar to condensate on viscosity and chemical characteristics.

Condensate pumps are designed for feed of turbine waste steam condensate, condensate of heating steam from heat exchangers of NPP power units and liquids similar to condensate on viscosity and chemical characteristics.

– According to design modifications pumps KsVA 900-180, KsVA 1000-190, KsVA 2200-100, KsVA 2200-170-1 are of centrifugal, vertical, double casing and multi staged type. They provide stable head at parallel operation of pumps and deficiency of air leak through operative and inoperative pump. Pumps are rated for operation with minimal available positive suction bead in vacuum at inlet at condensate temperature close to saturation temperature. To improve anticavitation characteristics before the first stage impeller it is installed booster impeller.

– Pumps KsVA 1500-240 are centrifugal, horizontal, single stage with double-entry impeller. They are designed for feed of condensate to deaerator.

Specification

| Pump type | Capacity, м3/hour | Нead, m | Rotation speed (synchr.), rpm | Motor power, kW | Pump overall dimensions, mm | Pump weight, kg |

| КsVА 900-180 | 900 | 180 | 1500 | 1000 | 1625 х 1700 х 5435 | 12760 |

| КsVА 1000-190 | 1040 | 190 | 1500 | 1000 | 1800 х 1700 х 5435 | 12760 |

| КsVА 1500-120 | 1500 | 120 | 750 | 1000 | 2200 х 3200 х 7875 | 12315 |

| КsVА 1500-120-1 | 1850 | 95 | 750 | 800 | 2185 х 2100 х 5225 | 20900 |

| КsVА 1500-120а | 1850 | 95 | 750 | 1000 | 2200 х 3200 х 6110 | 22000 |

| КsА 1500-240-2 | 1500 | 240 | 3000 | 1600 | 4810 х 1800 х 1685 | 8750 |

| КsA 1500-240-2а | 1850 | 170 | 3000 | 1600 | 4810 х 1800 х 1685 | 8750 |

| КsV 2200-100 | 2200 | 100 | 1500 | 1000 | 1895 х 1960 х 6210 | 18360 |

| АКsVА 2200-170-1 | 2200 | 170 | 1500 | 1600 | 1960 х 2100 х 7165 | 18250 |

| АКsVА 1500-120-2 | 1850* | 95* | 750 | 800 | 2100 х 2277 х 5383 | 21100 |

| АКsVА 2200-220-1 | 2200* | 211* | 1500 | 2000 | 2309 х 2684 х 6805 | 23400 |

* – at current frequency 49 Hz

The pumps are applied in different systems of NPP power units and designed for pumping out and feeding of process, chemical, neutral and aggressive medium.

The pumps are applied in different systems of NPP power units and designed for pumping out and feeding of process, chemical, neutral and aggressive medium.

Cradle-mounted pumps are centrifugal, single stage, horizontal with forged or cast casing.

Material of casing is austenitic or carbon steel.

Electric motor is used as a pump drive. Motor and pump shafts are connected with flexible plate coupling or pin coupling.

Rotor shaft is sealed with mechanical end seal. Axial forces are balanced by devices connecting discharge and suction chambers of the pump.

Specification

| Pump type | Capacity, м3/hour | Нead, m | Rotational speed (synchr.), rpm | Motor power, kW | Pump overall dimensions, mm | Pump weight, kg |

| CNА 100/50 | 100 | 50 | 3000 | 22 | 1620 x 711 х 410 | 550 |

| CNА 100-50-2 | 100 | 50 | 3000 | 22 | 1620 х 712 х 445 | 510 |

| АCNА 100-50-3 | 102 | 52 | 3000 | 30 | 1465 х 640 х 470 | 500 |

| АCNА 100-50-4 | 100 | 50 | 3000 | 30 | 1465 х 640 х 415 | 440 |

| CNА 25/52 | 25 | 52 | 3000 | 11 | 1360 x 518 х414 | 390 |

| АCNА 200-120 | 200 | 1 20 | 3000 | 110 | 2245 х 950 х 680 | 1360 |

| CN 250-20 | 250 | 20 | 1500 | 22 | 1807 x 630 x 859 | 650 |

| CNА 6000-30 | 6048 | 30.6 | 1000 | 800 | 5170 x 2020 x 1780 | 11000 |

| CNА 600-25 | 600 | 25 | 1000 | 75 | 2475 х 920 х 1350 | 2000 |

| CN 400-40 | 400 | 40 | 1500 | 90 | 2605 х 1265 х 1160 | 1700 |

| CN 420-45 | 420 | 45 | 1500 | 90 | 2225 x 670 x 915 | 1500 |

| CN 2500-70 | 2500 | 70 | 8000 | 800 | 4290 х 1680 х 2405 | 12000 |

The pumps are designed for supply of feed water to steam generators of nuclear power plants.

The pumps are designed for supply of feed water to steam generators of nuclear power plants.

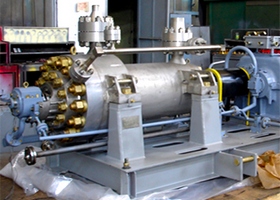

Feed water pumps are centrifugal, multi stage, horizontal, single or double sectional.

In new designs double casing modification is applied, that makes possible to decrease considerably the time and to reduce labour costs for pump revision and repairing.

Electric motor is used as a pump drive.

Specification

| Pump type | Capacity, м3/hour | Head, m | Rotational speed (synchr.), rpm | Motor power, кВт | Pump overall dimensions, mm | Pump weight, kg |

| PEА 65-50 | 65 | 580 | 3000 | 200 | 3135 х 1030 х 1100 | 3100 |

| PEА 150-85 | 150 | 918 | 3000 | 800 | 4285 х 1210 х 1225 | 6800 |

| PEА 850-65 | 850 | 714 | 3000 | 2500 | 5415 х 1680 х 1620 | 13730 |

| PEА 1650-80 | 1650 | 910 | 3000 | 5000 | 6605 х 2130 х 2000 | 26300 |

| PEА 1650-80а | 1650 | 830 | 3000 | 5000 | 6605 х 2130 х 2000 | 26300 |

| АPEА 1150-75 | 1154 | 760 | 3000 | 3500 | 8850 х 2925 х 1975 | 20000 |

| CN 150-90 | 150 | 910 | 3000 | 800 | 4260 х 1120 х 1409 | 6200 |

| CN 150-90Г | 150 | 910 | 3000 | 800 | 4260 х 1275 х 1409 | 6650 |

| PEА 150-85-1 | 150* | 850* | 3000 | 630 | 4390 х 1490 х 1940 | 7310 |

| АCNА 150-90-1 | 150 | 900 | 2973 | 525 | 4417 х 1380 х 1600 | 6600 |

| АCNА 150-90-2 | 190 | 900 | 2982 | 665 | 4390 х 1380 х 1140 | 7000 |

* – at current frequency 49 Hz

Special purpose pumps are applied in special systems of NPP units with reactors VVER-1000 PBMK (coolant makeup system, aftercooling system, sprin¬kler system, fire fighting system).

Special purpose pumps are applied in special systems of NPP units with reactors VVER-1000 PBMK (coolant makeup system, aftercooling system, sprin¬kler system, fire fighting system).

Special purpose pumps are centrifugal, multi stage or with double-entry impeller, horizontal, with forged or cast casing. Casing material is austenitic steel. Electric motor is used as a pump drive. Motor and pump drive are connected by gear-type or flexible plate coupling.

Rotor of pump shaft is sealed by mechanical end seal. Axial force relief is compensated in most cases by hydraulic discharging device.

Specification

| Pump type | Capacity, м3/hour | Head, m | Rotational speed (synchr.), rpm | Morot power, kW | Pump overall dimensions, mm | Pump weight, kg |

| CN 50-135 | 50 | 1320 | 9000 | 500 | 5145 х 1511 х 1345 | 10300 |

| CN 60-180 | 60 | 1780 | 9000 | 800 | 5355 х 1511 х 1465 | 11030 |

| АCNА 25-180 | 25 | 1820 | 6000 | 400 | 4717 х 1565 x 1325 | 6300 |

| АCNА 60-185 | 60 | 1850 | 3000 | 800 | 4925 х 1500 х 1435 | 8390 |

| АCNА 60-185-1 | 60* | 1613* | 3000 | 800 | 4865 х 1360 х 1465 | 8520 |

| CNА 125-80 | 125* | 80* | 3000 | 55 | 2380 х 1362 х 1710 | 1800 |

| CNА 200-180 | 160* | 145* | 3000 | 110 | 2655 х 850 х 1650 | 2350 |

| АCNА 400-100 | 400 | 100 | 3000 | 315 | 3380 х 1350 х 1335 | 3115 |

| АCNА 400-100Е | 300 | 80 | 2970 | 90 | 2650 х 1035 х 1205 | 2530 |

| АCNА 400-100-1 | 400* | 90* | 3000 | 160 | 2715 х 1200 х 1200 | 3430 |

| D800-56 | 800 | 56 | 1500 | 200 | 3090 х 960 х 918 | 3250 |

| АCNА 50-90 | 48,2 | 930 | 2976 | 315 | 3928 х 1285 х 1075 | 4500 |

| CNSА 800-90 | 800 | 90 | 1500 | 250 | 1390 х 1125 х 1000 | 1800 |

* – at current frequency 49 Hz

II. CUSTOMIZED EQUIPMENT FOR NPP

JSC “SMNPO-Engineering” has experience in the development and manufacture of customized equipment for nuclear power plants.

|  |  |  |

The Company produced the lot of embedded elementsand metal structures of different types and modifications in the construction of storage facility for spent nuclear fuel (ISF-2) on the Chernobyl nuclear power plant.

The process of laying the spent fuel in special capsules for further storage will be carried out with their help. This equipment has been thoroughly tested for conformity to product requirements for the nuclear industry.

4 safety door units – one to isolate the concrete module, three – intermediate have been manufactured as well . The doors are made using large thicknesses metal, the layer of lead shot, etc. Their weight varies within 5-13.5 tons.

In 2014 Sumy engineers designed and phasing produced 20 tanks with capacity from 0.09 to 16 cubic meters for the assembly of the first and second power units of the Belarusian nuclear power plant.

III. GAS TURBINE POWER GENERATION PLANTS

The promising trend in power engineering development is application of energy-saving technologies on the basis of gas turbine power plants, which permit essentially increasing the efficiency of organic fuel usage in the process of combined production of thermal and electric energy.

Having many years experience in design and manufacture of turbo compressor gas turbine driven compressor units the JSC «Sumy NPO» has mastered production of gas turbine power plants:

– Gas turbine driven cogeneration plant (GTDCP-16) provides the production of 16 MW power and 21.5 Gcal/h thermal energy.

– Combined-cycle power generation plant (CCPGP-20) comprises the gas turbine power unit (GTU) with 16 MW power and steam turbine power plant with 6 MW rated power.

Application of cogeneration plants data allows to solve the following tasks:

– utilization of casing-head gas;

– the cost reducing of electricity consumed for own needs;

– generation of emergency stand-by power;

– heating of residential-grade buildings and housing settlements.

– heating of residential-grade buildings and housing settlements.

The advantages of block-container arrangement for gas turbine zone and technical decisions, traditional for heat-and-power engineering, specified the location of the electric generator and other power generating equipment in solid building are applied in the plants design. The plant can be made completely in block-container design of full factory readiness, which considerably shorten construction and assembling work period.

The main advantages of the power plants are the following:

– the possibility of mounting in solid buildings (renovation for exiting ones) and at open platforms (block-modular design);

– mobility, the possibility for mounting in direct closeness to consumer or gas source;

– block-modular design permits to mount and to repair equipment at limited area;

– the possibility for quick switching off and starting-up of power plant within 15-45 minutes;

– automatic control system and wide diagnosing for technical conditions;

– minimum number of maintenance personnel.

Main characteristics

Characteristic, measuring unit | Value of characteristic | |

CCPGP – 20 | GTDCP – 16 | |

Gas-turbogenerator plant (GTP) | ||

Generator type | Т 20-2-У3 | |

– active electric power on terminals of generator in rated conditions, MW | 16 | |

– rated voltage on terminals of generator, V | 6300 (10500) | |

– rated current frequency, Hz | 50 | |

– nominal power factor, cos | 0.8 | |

Steam waste heat boiler | – | |

– outlet steam temperature, °C, no more than | 380 | – |

– outlet steam pressure, MPa | 2.0 | – |

Heat recovery unit | – | |

– water discharge, m3/h | – | 480 |

Steam turbine unit ( STU) | ||

Steam turbine (ST) | – | |

– steam turbine power , MW | 4.0-6.0 | – |

– steam flow rate, t/h | 32.6 | – |

– ST inlet steam pressure, MPa | 1.75 | – |

Generator type | T-6-2У3 | – |

– power electrical active on generator connecting terminals at nominal mode, MWт | 6.0 | – |

– voltage nominal on generator connecting terminals, V | 6300 ( 10500) | – |

– current rate nominal, Hz | 50 | – |

– power factor nominal, cos | 0.8 | – |

When ordering the equipment which is been interested in, please fill in the Questionnaire.