Home » About the Company » Manufacturing Capabilities » Cold-finished and finned tubes production

JSC “SMNPO – Engineering” has a great experience in tubulars manufacture and currently manufactures tubes by cold rolling; by welding of carbon steels, stainless steels and non-ferrous metals and bimetallic finned tubes, which are used for heatexchangers.

Manufactured tubes assortment:

a) seamless cold-finished tubes

Outer diameter is from 6 up to 60 mm; wall thickness = from 1 up to 10 mm; made of different grades of steel, non-ferrous metals and alloys, usual, high and precision accuracy, in particular as to GOST:

Maximum length of manufactured tubes is 23 m.

Billet: hot-finished tubes as to GOST 8731; GOST 9940; Specifications TU 14-3-460 (or cold-finished tubes).

b) corrosion-resistant steel electric welded cold-finished tubes

Specifications TU U 27.2-8-66-2003; outer diameter is from 8 up to 76 mm; wall thickness is from 1 up to 3 mm.

Maximum length of manufactured tubes is 23 m.

Billet: GOST 11068 Ø 60х3; 89х3.

Total production capacity – 1400 tons (1030 thousand linear meters)

Cold-finished production area is equipped with:

1. Two KhPT 75–4В mills with tandem type saddle;

2. Two KhPTR 15–30 mills with rolls saddle;

3. Sinking mill of 30 kN forcing.

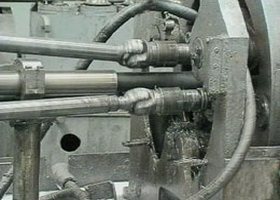

KhPT 75–4В mill (cold pilger tube rolling mill with tandem roll saddle)

This unique mill with 1200 kN maximum vertical forcing on roller is designed for cold rolling of tubes of different metals and alloys, manufactured tubes range is Ø18-102 mm. Rolling is carried out on stationary internal tool in two rows of reciprocating rollers provided with grooves semi-discs with passes of removable profile.

Billet outer diameter is 38÷89 (104) mm; billet length is 1.5 ÷ 7 m; billet wall thickness is 2.5 ÷ 14 mm; finished tubes outer diameter is 18 ÷ 76 (102) mm; rolled tubes length is up to 40 m;

Finished tubes wall thickness is 1 ÷ 10 mm; capacity – 50-150 m/h.

KhPTR 15 – 30 mill (cold pilger tube rolling mill with “roller” saddle)

Upgraded ХПТР 15 – 30 mill is designed for cold rolling of tubes of different metals and alloys, manufactured tubes range is Ø10 ÷ 32 mm. Rolling is carried out on stationary internal tool in a couple of reciprocating rollers provided with ring dies with passes of removable profile.

Billet diameter – 18 ÷ 38 mm; billet length – 1.5 ÷ 11 m; billet wall thickness – 1.2 ÷ 3.5 mm;

finished tubes diameter – 10 ÷ 32 mm; finished tubes length – 2 ÷ 23 m; Finished tubes wall thickness – 1 ÷ 3 mm; capacity – 10-50 m/h.

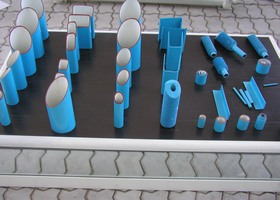

To increase tubes heat transfer area in heat exchangers two finning methods – HF and rotary extrusion – are used.

The following equipment is used:

Tubes HF spiral finning machine with VChS4-160/0.44 generator

Machine for spiral rotary finning on steel-aluminium heat transfer tubes