Home » Products » Compressor Equipment » Reciprocating Compressors » Compressors for Ethylene and Polyethylene Production

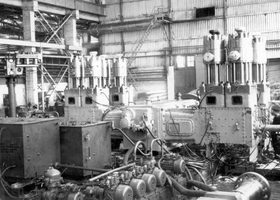

These are designed to compress a polyethylene in «Polymir» type processing lines for low density polyethylene production applying a method of high pressure.

Fresh ethylene compressors (LP compressors) are made on the opposite base 4M16 with three stages and electric drive that ensures smooth adjustment of capacity by changing the rotational speed from 100 to 320 rpm/min.

Reaction pressure compressors (HP compressors) are made on the opposite base 4M40 with hydro mechanical transmission of motion from cranking mechanism to actuating elements of cylinder of both stages.

Reciprocating mechanism is lubricated by oil circulated under pressure being produced by pump. Cylinders and sealing devices of the rods are force lubricated under pressure being produced by multi-plunger pump. These are cooled by water with close discharge.

Automatic monitoring, control and protection system ensures a remote programmed start up and shutdown of the compressor, warning and alarm signaling, as well as blocking of driving electric motor on parameters deviation from the set values.

Specification

Compressor | Compressed | Capacity | Abs. Pressure, | Consumed | Engine’s type | ||

m3/min | Standard | suction | discharge | ||||

4GM16-12.5/17-281 | Ethylene | 12.5 | 137 | 1.7 | 28.1 | 870 | Electric motor |

4GМ16-14/14-281 | Ethylene | 14 | 164 | 1.4 | 28.1 | 1100 | Electric motor |

| 4GМ16-14/15-104 | Ethylene | 14 | 348 | 1.5 | 10.4 | 962 | Electric motor |

4GМ40-1.2/250-2500 | Ethylene | 1.12 | 260 | 25.0 | 250.0 | 4300 | Electric motor |

When ordering the equipment which is been interested in, please fill in the Questionnaire.

Details are specified in the Technical Catalog “Reciprocating Compressors“.