|  |

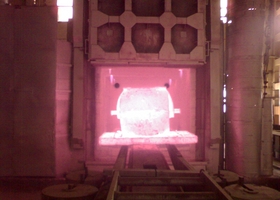

| Aging of cast iron castings and heat treatment of welded structures in bogie hearth gas chamber furnace | |

|  |

Heat treatment of castings and forgings |

|

|

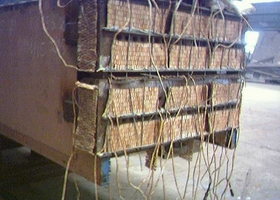

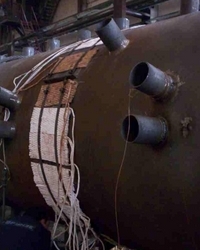

Welded seams local heat treatment fulfilment

Currently, JSC “SMNPO – Engineering” has the ability to provide services for heat treatment of blanks, parts and welded structures according to the modes and technological processes of the Customer:

1. For rough blanks (castings, forgings and rolled blanks): |

|

| 2. For pre-treated products: |

|

| 3. For welded structures: |

|

When performing heat treatment, unique modern gas and electric furnaces (shaft, chamber and bogie hearth furnaces) with a maximum heating temperature of up to 1100 °C, as well as units for local heating with a maximum heating temperature of up to 700 °C are used.

Maximum working dimensions of the equipment being used:

| aging of cast iron casting | 3500 × 7500 × 3000 mm | max weight up to 20 t |

annealing and normalizing | 2900 × 4000 × 800 mm | max weight up to 10 t |

| quenching in water | 2900 × 4000 × 800 mm | max weight up to 10 t |

| quenching in oil | 2700 × 3000 × 1700 mm | max weight up to 5 t |

| shaft quenching in water | Ø500 × 7000 mm | max weight up to 7 t |

| shaft quenching in oil | Ø500 × 7000 mm | max weight up to 5 t |

| welded structures tempering | 5000 × 8000 × 3000 mm | max weight up to 50 t |

Also, JSC “SMNPO – Engineering” has the necessary equipment to perform local heat treatment (tempering for stress relieving after welding) of welded seams with total length of up to 9000 mm and seam thickness of up to 90 mm.